Subtotal: ₨ 1,000

3D Printer Transforms To CNC Leave a comment

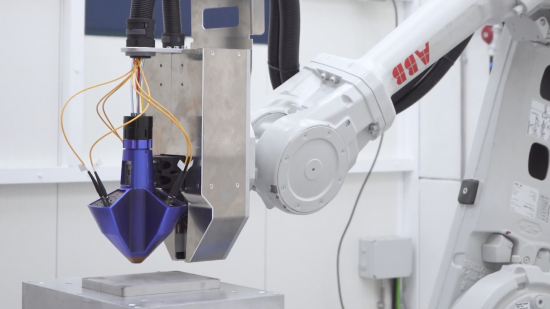

Superficially, it is simple to consider changing a three-D printer right into a CNC machine. After all, they each do basically the identical thing. They circulate a device round in 3 dimensions. Reducing this to practice, however, is a problem. A CNC device in all likelihood weighs extra than a regular hotel. In addition, slicing into strong fabric generates quite a few torques.

[Thomas Sanladerer] knew all this, however desired to attempt a conversion anyway. He had some printers to choose from, and he selected a totally robust MendelMax 3. He wasn’t positive he’d land up with a realistic machine, however, he desired to do it for the instructional value, at the least. The result, as you could see withinside the video below, surpassed his expectations.

The ensuing tool can paintings wood, acrylic, or even aluminum. This required some adjustments to the printer, though. A lot of the MendelMax is 1 mm sheet metal. [Thomas] changed quite a few components with beefy three-D-revealed components and MDF. He additionally decreased the Y-axis journey a chunk to make the mattress extra stable. The software program becomes basically left unchanged however has a few configuration adjustments that he explains.

The first incarnation used a cheaper rotary device as a spindle. However, the strain on the device might reason it to fail after a chunk of use. [Thomas] was given a forty-eight V spindle motor and an identical strength deliver that works well.

The effects are good, despite the fact that now no longer perfect. [Thomas] nevertheless desires to transfer out a few belts and improve the Z-axis extra. Still, it seems quite useful. We aren’t positive all three-D printers might be as smooth to stiffen as tons because of the MendelMax. Still, this construct proves that it is able to be done, at the least for a few printers.

An extra not unusual place technique is to apply your three-D printer to construct a CNC machine. Of course, changing the alternative way (that is, CNC to the three-D printer) is nearly trivial. Another choice is to mount a LASER that doesn’t have torque problems. Of course, you would possibly have protection issues, however, that’s some other hurdle to clear.

Boya Mic M1 Lavalier Collar Microphone for Canon Nikon DSLR Camcorder & Phone Android iPhone BY-M1 Mic in Pakistan

Boya Mic M1 Lavalier Collar Microphone for Canon Nikon DSLR Camcorder & Phone Android iPhone BY-M1 Mic in Pakistan