Everything About Peltier Elements and Their Applications Leave a comment

Peltier elements, also known as thermoelectric coolers (TECs), transfer heat from one side to the other based on the direction of electric current. TEC controllers regulate and drive Peltier elements to ensure efficient operation.

This article explains how Peltier elements work, highlights their features, and lists manufacturers that produce them.

How Peltier Elements Work

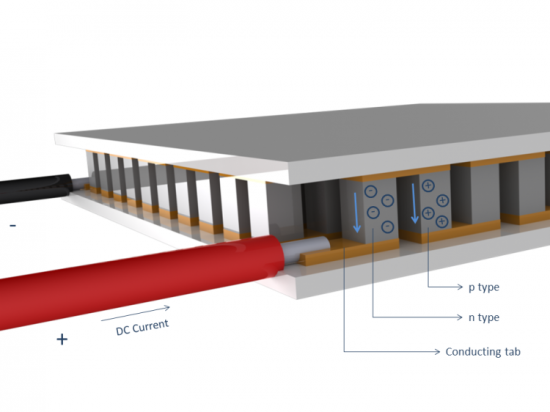

A Peltier element moves heat using the Peltier effect. When electric current flows through the element, it creates a temperature difference between its two surfaces. By changing the direction of the DC current, you can make the element either cool or heat without altering its physical setup.

Key Features of Peltier Elements

- Compact design allows integration into small devices.

- No moving parts make them highly reliable and silent.

- TEC controllers regulate the current flow to maintain precise temperatures.

Manufacturers print identification markings on the cold side of a Peltier element. If you connect the positive supply voltage to the red wire, this marked side remains cold.

To maintain cooling efficiency, manufacturers connect power cables to the hot side instead of the cold side, preventing unwanted thermal losses.

Different Types of Peltier Elements

- Sizes: Ranges from 1 mm × 1 mm to 60 mm × 60 mm.

- Shapes: Square, ring-shaped, multi-stage, single-stage, sealed, or non-sealed custom designs.

- Temperature Range: Multi-stage models achieve up to 130°C, with a maximum operating temperature of 200°C.

- Cooling Capacity: Supports cooling power up to 290 W.

Understanding Peltier Element Behavior

A Peltier element follows three main principles:

- Peltier Effect (Qp) – Transfers heat from one side to the other, calculated as: Qp=I×α×TQp = I \times α \times T

- Heat Backflow (QRth) – Heat naturally flows from the hot side to the cold side: QRth=ΔTRthQRth = \frac{\Delta T}{Rth}

- Joule Heating (QRv) – Electrical resistance generates heat, described by: QRv=I2×Rv2QRv = \frac{I^2 \times Rv}{2}

The hot side dissipates excess heat through a heat sink, preventing performance loss. The net cooling capacity (Qc) depends on these three effects and follows this equation:

Qc=Qp−QRth−QRvQc = Qp – QRth – QRv

Key Performance Parameters

Manufacturers provide four essential parameters to describe Peltier element performance:

- Qmax – Maximum heat transfer capacity at a zero-degree temperature difference between the hot and cold sides.

- Tmax – Maximum temperature difference the element can reach when transferring no heat.

- Imax – Maximum current the element draws at Qmax.

- Umax – Maximum voltage the element operates at when reaching Qmax.

Important Note:

You will never reach Qmax or Tmax in real-world applications because of efficiency losses. These values serve as theoretical reference points to compare Peltier modules.

When designing a thermoelectric system, you must balance heat transfer capacity (Qc) and temperature difference (ΔT) for optimal performance.

How Peltier Elements Perform in Real Applications

You can analyze a Peltier element’s performance using characteristic graphs. Leading manufacturers, such as Ferrotec, use these graphs to demonstrate behavior under different conditions. These diagrams help engineers understand how Peltier elements function in practical applications.

Key Factors That Affect Peltier Performance

- Efficiency – Works best in small-scale cooling applications due to power consumption limits.

- Thermal Management – Needs a heat sink to remove excess heat from the hot side.

- Power Consumption – Requires a TEC controller for precise control and efficiency.

- Durability – Lasts for years without failure since it has no moving parts.

Common Applications of Peltier Elements

Peltier elements offer reliable cooling and heating for various industries. Engineers use them in electronics, automotive, medical, and industrial applications.

Where You’ll Find Peltier Elements

- Electronics Cooling – CPU coolers, laser diode cooling, and infrared camera stabilization.

- Medical Devices – Vaccine storage, DNA sequencing, and portable refrigeration units.

- Automotive – Seat coolers, cup holders, and temperature-controlled compartments.

- Industrial Use – Precision temperature regulation in experiments and process control.

- Aerospace – Satellite and spacecraft thermal management.

Conclusion

The Peltier element plays a crucial role in modern cooling and heating technology. By applying the Peltier effect, these elements offer precise thermal control without relying on mechanical parts. If you need compact, silent, and reliable temperature control, Peltier elements provide an excellent solution for many industries.

However, engineers must consider efficiency trade-offs and proper thermal management to maximize performance. Would you like recommendations on the best Peltier elements for your specific application or want to buy them? Contact us now!